Handling the Freezteq Original Stick must be conducted whilst wearing the full recommended Personal Protection Equipment. The Safety Data Sheet must be read prior to using the product.

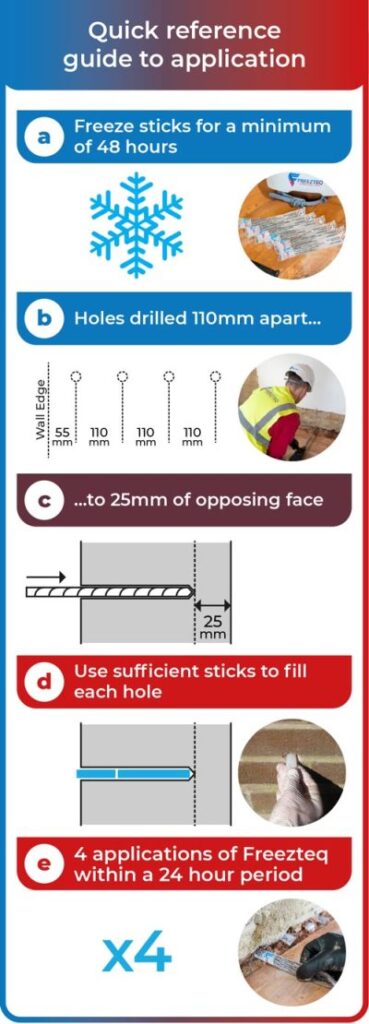

Before any installation the Freezteq sticks must be placed in a freezer for a minimum of 48 hours. The sticks must be completely frozen solid. They cannot be applied or cut until they have reached this state.

The defective wall finishes must be removed to a minimum height 300mm above the level of the ‘salt line’, or 1 metre above the original DPC, whichever is the higher of the two.

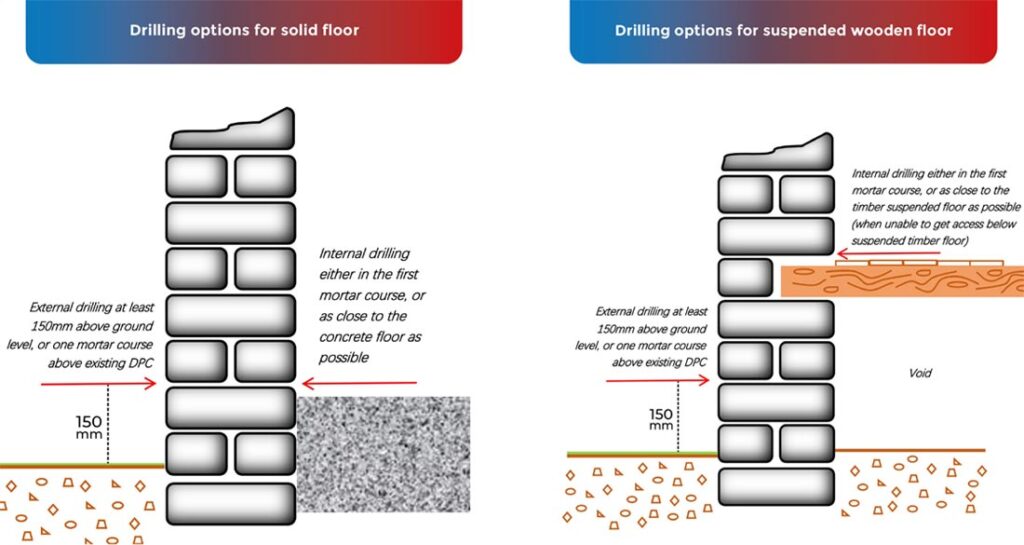

Drilling may be carried out either internally or externally.

The drilled holes should be made with a 22mm dia. drill bit.

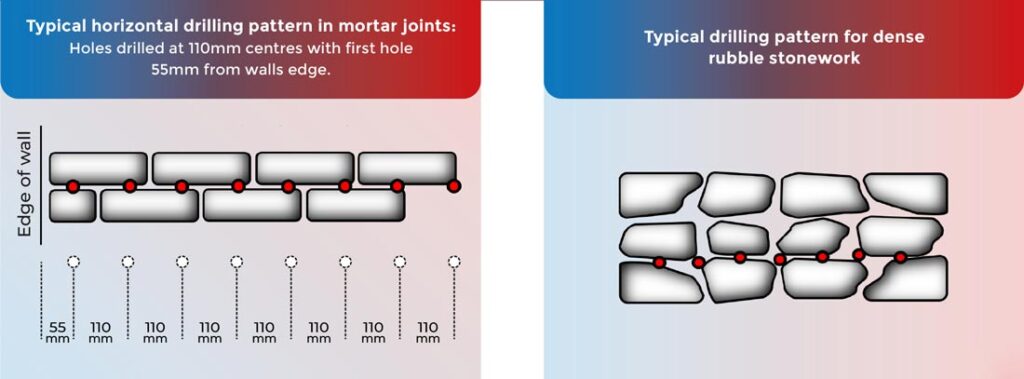

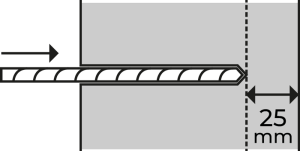

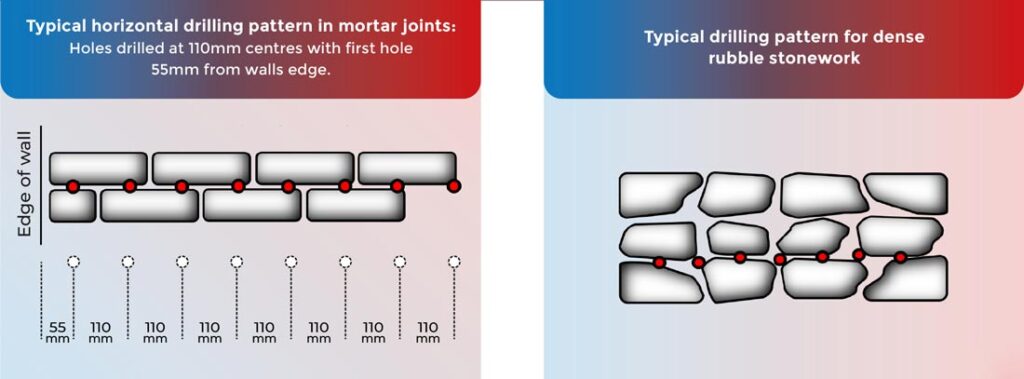

When drilling into the wall, the hole should be to a depth of 25mm of the opposing face. (As shown.)

The first hole must be drilled 55mm from the wall’s edge.

The second and subsequent holes must be drilled 110mm apart. (Measurements must be taken centre to centre of each hole).

External Applications

• a minimum of 150mm above ground level.

Or

• one mortar course above the existing DPC that has ceased to be effective.

Internal Applications

If the holes are to be made from the internal side, drill the holes as close as is possible to the floor’s surface, or in to the first horizontal joint above the internal floor’s surface (Note: assuming it is not possible to get access below the suspended timber floor).

Once the first application has been made, the remaining 3 applications should be made within a 24-hour period. Beyond this time frame there is a higher probability of the treated substrate trying to refuse the final applications of Freezteq Original, thus limiting the efficacy of the treatment.

The frozen stick of Freezteq can be cut out of the sachet simply using a pair of scissors or a knife.

Push the frozen stick of Freezteq Original into the pre-drilled hole. The sticks should be pushed completely into each pre-drilled hole. Sufficient sticks must be used to fill the hole completely. The number of sticks used is dependent on the thickness of the wall.

If a whole stick cannot be inserted completely, break the protruding part off and use it in the next hole.

When all holes have been filled completely, this is classified as one application.

Once the first application has completely melted, the process is repeated until a total of FOUR applications have been made within each hole.

Once the first application has been made, the remaining three applications should be made within a 24-hour period. Beyond this time frame there is a higher probability of the treated substrate trying to refuse the final applications of Freezteq Original, thus limiting the efficacy of the treatment.

250 Freezteq sticks will typically treat an approximate length of between 5.75 and 6.0 metres of 225mm thickness wall. Please note usage is dependent upon environmental, structural, and other conditions

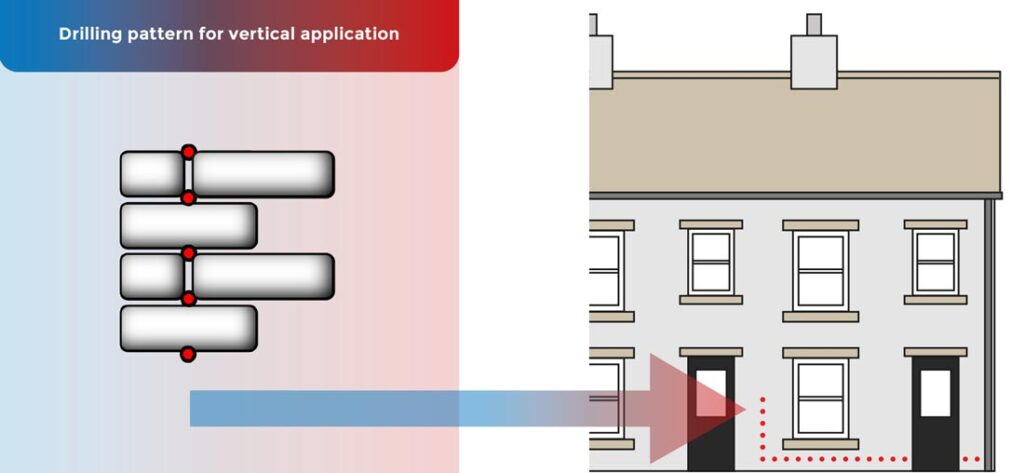

Where a Freezteq Original application is adjoining another structure, it may be necessary to install a vertical DPC.

Additional holes should be drilled vertically to a height of 1.2m-1.5m following the mortar line. Once this has been completed, four applications of Freezteq Original are to be carried out as previously described.

Following the Freezteq Original application, holes must be filled using an appropriate strength mortar to maintain the structural integrity of the wall. Independent technical advice should be sought with regards to the integrity of the structure.

Reinstatement of finishes should be undertaken using the Freezteq Breathable Render System.

Standards may vary from region to region. The user should make contact with their local approval body prior to carrying out any work so as to ensure they are fully compliant with any standards that are enforce.

Please read this installation guide carefully before installing any Freezteq products.

This installation guide should be read in conjunction with the material safety data sheets prior to the handling of using the Freezteq products. The full recommended personal protection equipment (PPE) must be worn at all times when handling the products.